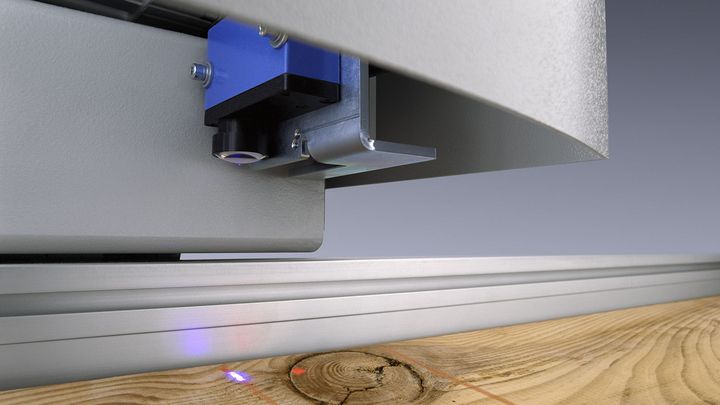

Laser photocell at pivoting pusher

Before the saw control can start efficient optimization, it needs some data regarding the input material. The laser photocell enables automatic detection of the raw board length in order to subsequently calculate the cutting patterns for the best possible material yield. Also, its position on the pivoting pusher supports an efficient and continuous workflow, since the next material can be placed in the processing position during processing.