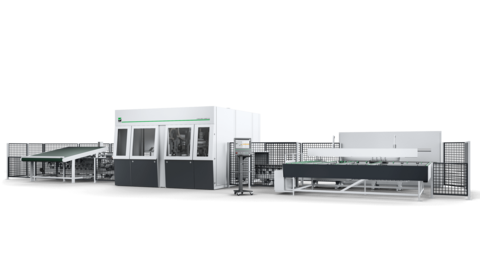

WEINIG SOLID CNC CR series: Best-in-class performance in all categories

The SOLID CNC CR series opens up a whole new WEINIG world in the windows and doors sector, facades and conservatories or the furniture sector. All the tried and trusted SOLID CNC CR benefits are now available for individual application in different performance categories: From the entry model “SOLID CNC CR Compact” to the high-performance professional “SOLID CNC CR 226”. Every SOLID CNC CR takes over the tasks of up to 5 machines in one single cycle. Maximum precision, full automation and high flexibility.

Processing of all known corner joints, longitudinal contour processing, drilling, shaping and insert shaping – a clear case for the SOLID CNC CR! Production types such as individual parts, series or frame-type window production in a completely new light: precise positioning with the clamping table, high flexibility with a tool storing rack and perfectly adjusted selection of units.

With the right software package and WEINIG as your partner for solid wood processing, we do not only offer you machines but the perfectly customized, future-oriented solutions. Everything from a single source - WEINIG.

All machines

CNC Machining Center SOLID CNC CR 400 V

XS machine, XXL possibilities

- PowerGrip single clamping table and PowerGrip Motion 3D table

- New machine cabin with improved visibility and accessibility for service and maintenance

- Thinking in new dimensions – part widths up to 330 mm

- WEINIG product integration - one data set for all production components

- Standard interfaces for industry software, e.g. for window/door production

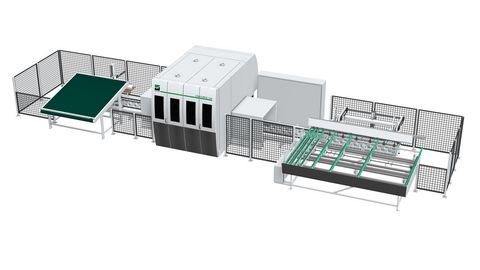

WEINIG SOLID CNC CR 300

The SOLID CNC CR for smaller shops with extended workpiece clamping options

- Powergrip RePos easy clamping table (as an option)

- No limit to the corner joint and window system possibilities

- It is possible to have everything from a single WEINIG source for complete solutions with machines - software - tools.

- WEINIG product integration - one data set for all production components

- Standard interfaces for industry software, e.g. window/door production, WOP or CAD/CAM software.

WEINIG SOLID CNC CR 124

The premium class all-rounder

- Low-vibration construction

- Advanced unit technology

- MBK – multiple spindle drilling head

- No limit to the corner joint possibilities

- Standard interfaces for industry software, e.g. window/door production, WOP or CAD/CAM software.

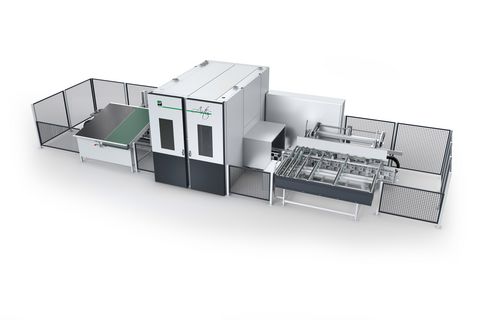

CNC machining centres SOLID CNC CR 500 V & 600 V

A new level of dynamics and flexibility

- PowerGrip Motion 2D/3D

- New machine cabin with improved visibility and accessibility for service and maintenance

- Thinking in new dimensions – part widths up to 330 mm

- Advanced unit technology

- No limit to the corner joint possibilities

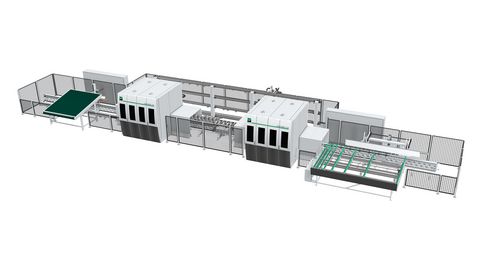

WEINIG SOLID CNC CR 226

Uncompromising dynamism and optimal performance

- Low-vibration construction

- Advanced unit technology

- MBK – multiple spindle drilling head

- No limit to the corner joint possibilities

- Standard interfaces for industry software, e.g. window/door production, WOP or CAD/CAM software.

The WEINIG SOLID CNC CR series offers you

- Complete processing in one clamping process

- Processing without processing times even for small lot sizes

- Automation enables less manpower in production

- Maximum flexibility as a result of the large tool magazine

- Energy feedback modules means savings in energy