BOND-4-YIELD System - New Technology for Optimal Value

The Innovation

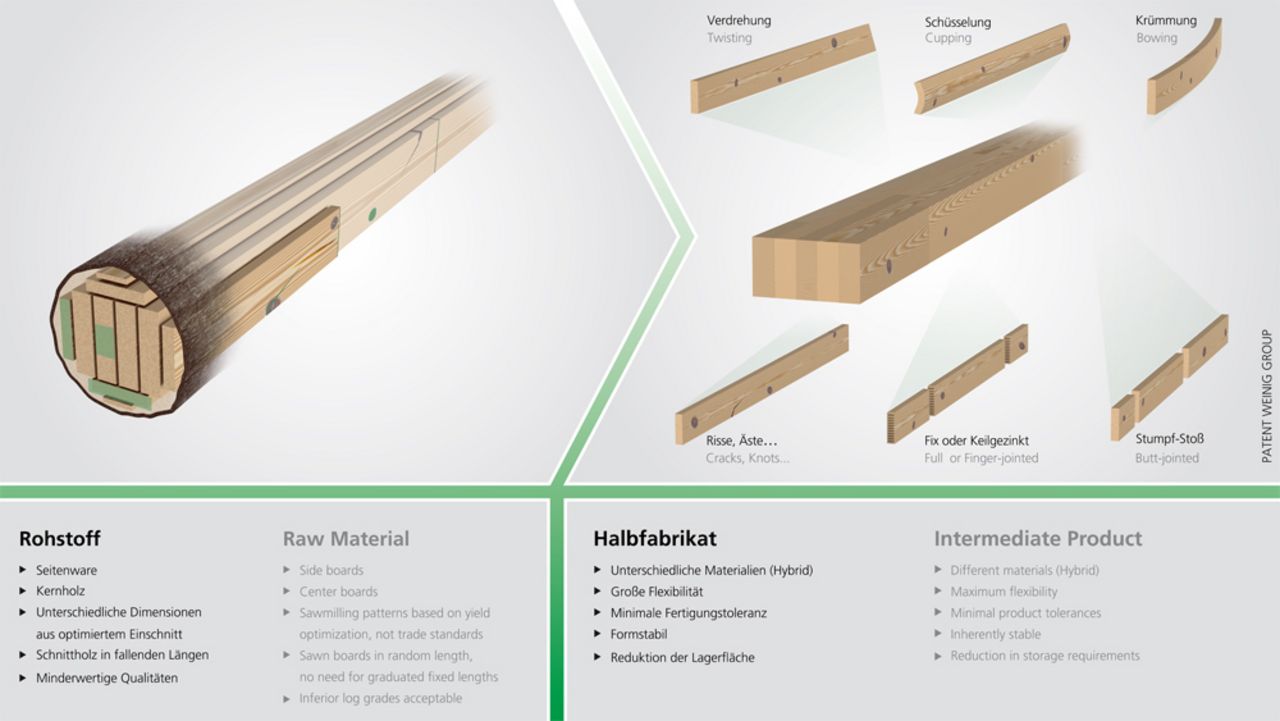

The added value begins with the cutting of the log, because the production of the laminated beam allows for the utilization of various timber dimensions regardless of the finished product.

By incorporating dimensions which do not meet “prevailing market dimensions”, the amount of material needlessly chipped away can be reduced for side boards. This new manufacturing technology allows for optimal wood yield by adapting to the thickness and width of the side boards. Even inferior quality center boards can be utilized. Cracks, loose knots and waney edges no longer pose processing constraints.

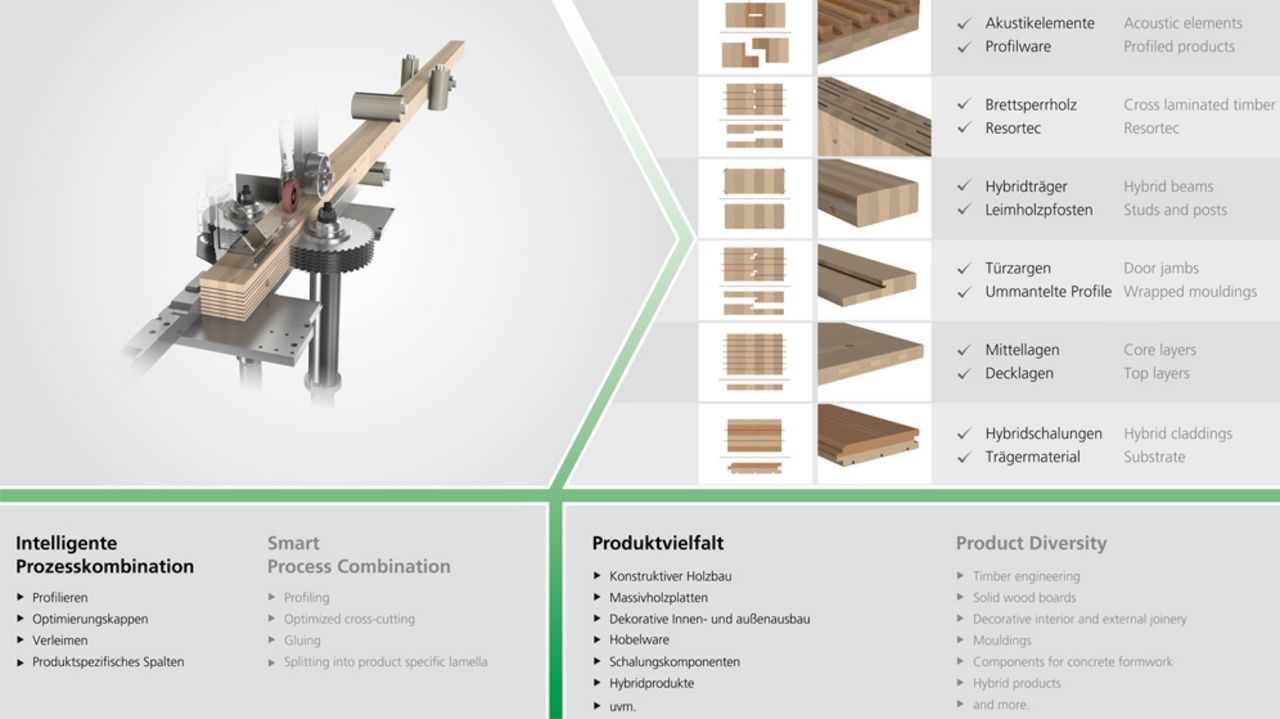

The production of a semi-finished product consisting of layered laminated boards which can later be split into lamellas perpendicular to the glued joints provides an optimal prefabricated base material for further industrial processing. Bond-4-Yield laminated beams are inherently stable and very strong. The wood defects are bonded in the laminated beam which enables highly automated processing and notably reduced labor costs.

Our system solution

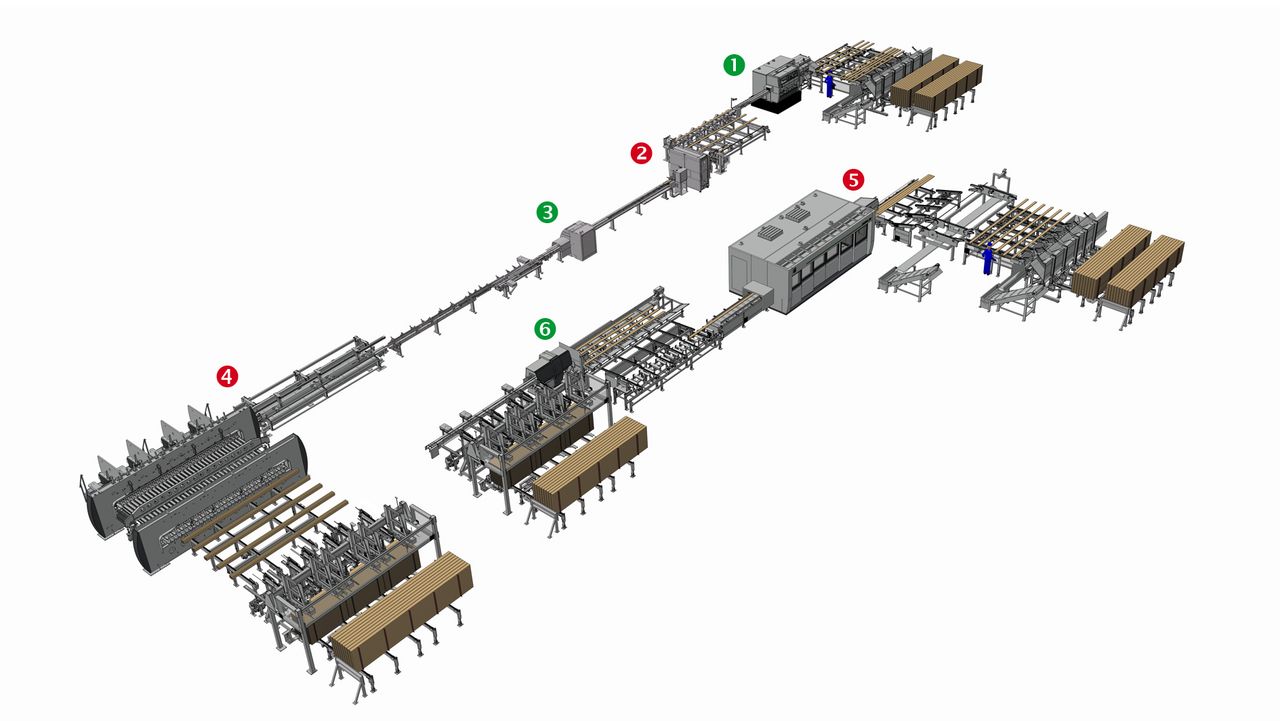

Butt jointed laminated beam manufacturing is a WEINIG patented technology. The production line is available in three performance categories ranging from the starter model for small companies to the highest configuration level see graphic).

Would you like to know more? We would be delighted to send you more details on all of our products or speak to you in person.